What we can do for the environment

Solutions to Global Warming

To achieve a low-carbon society, we are working on initiatives for global warming solutions such as energy saving efforts in our offices and factories.

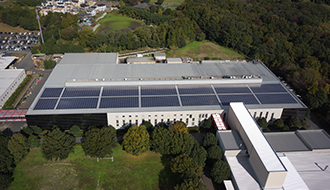

Solar Power Supply Business

“PLUS Maebashi Plant Power Station” has been selling full electric power generated by solar thermal system to TEPCO (Tokyo Electric Power Company) since November 2013.

The solar panels installed on the roof of the factory can output 500kW of electricity and generate approx. 555,935kWh in 2019.

The business starts as one of our initiatives to reduce CO2 emission, taking an advantage of Excess Electricity Purchasing Scheme for Renewable Energy (“Feed-In Tariff Scheme for Renewable Energy”) launched by METI (Ministry of Economy, Trade and Industry) in July 2012.

We have strengthened our environmental initiatives in recent years with the aim of building the ideal system for the environment (and thus society) that PLUS Group Environmental Philosophy seeks to achieve. Our ongoing efforts to achieve environmentally-friendly factories include the adoption of high-efficiency lighting in July 2011 and the installation of a powder coating line in August 2013. In total, our environmental initiatives implemented in the PLUS Maebashi Plant have resulted in reduction of CO2 emission by over 365 tons per year.

Reuse of Waste Heat from Large-Scale Precipitator

The machining process of furniture production emits an abundance of sawdust. In our Atelier Factory*1 located within PLUS LAND*2 , we collect such sawdust and separate “dusty air” from “larger pieces of sawdust”, then purify the collected air with large-scale precipitator to reuse the heat emitted from the precipitator for air-heating in our plant.

- *1 Atelier Factory

Factory for wooden furniture production, furnished with a studio for researching prototypes and handling custom-made orders. - *2 PLUS LAND

An industrial complex built in a suburb of Maebashi City, Gunma Prefecture. Surrounded by nature, the complex includes an office furniture plant, a factory for wooden furniture, a distribution center, an office, a training center, and so on. Since its establishment in 1991, it has been our production hub of office furniture products.

Introduction of the Top Light system

As part of our initiative to conserve energy, we placed large lightning windows in key areas of the ceiling of our Atelier Factory to introduce the sunlight into a plant building, so called “The top light system”. It enables to take sun light in three times as much as openings/windows located on the walls get, and is significantly effective for lighting large building such as factory because sunlight from wall windows is quite difficult to reach the center of the building.

Use of Roof insulation material

The roof of our Atelier factory is lined with insulating material to promote energy saving. It reduces the impact of outside temperature, and thus decreases the consumption of energy sources such as electricity, gas, and oil for air conditioning in the factory.

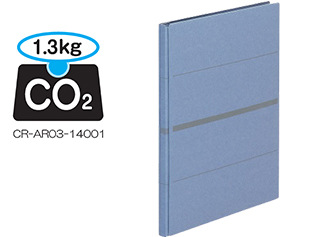

CFP-Certified Products: Participation in JEMAI CFP Program

With the update of CFP-PCR(Carbon Footprint of a Product*1 -Product Category Rule)in August 2013, our high capacity expandable file “ZERO-MAX” and desk mat products were certified as “CFP-Certified Products”by JEMAI (Japan Environmental Management Association for Industry) in January 2014. We calculate CFP value of our products based on new CFP-PCR standard, and the learnings from the program is being utilized for the development of future products and services, along with continuing efforts to reduce CO2 emissions for achieving a low-carbon society.

- *1 Carbon footprint

The carbon footprint, or Carbon Footprint of Products, is a scheme of calculating and indicating the total CO2 emissions generated throughout the life cycle of a product or service, from procurement of raw materials to disposal or recycling.