What we can do for our customers

Quality Control

We strive to provide safe and reliable products and services based on the PLUS Quality Policy.

PLUS Group Quality Policy

- 1. To provide our customers safe products and services, we work to improve our technology, and to create frameworks for an environmental protection and quality assurance.

- 2. We comply with laws and regulations, strive to improve the accuracy control through regular inspections of operations based on global standard quality control system.

- 3. We carry out the necessary process management in compliance with a process under safe working conditions to ensure quality stability or our products and services.

- 4. We work with our supplier and trading partners to ensure quality and safety of source, and conduct transactions based on fair agreements.

- 5. In the event of a quality issue with products or services, we report and disclose the case according to laws and regulations, carry out appropriate subsequent measures, and conduct an investigation to determine the cause to prevent reoccurrence.

- 6. We appreciate reports, complaints and feedbacks concerning quality issues from the customers, and deepen trusting relationship in the process of gathering such information.

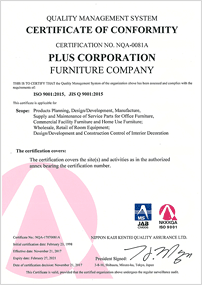

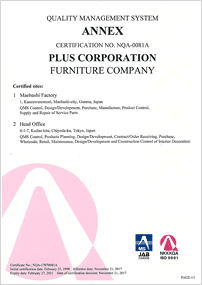

ISO9001 Certification

In 1998, PLUS Maebashi Plant gained ISO9001 certification aiming to strengthen our QA framework and to increase customer satisfactions. ISO9001 standard quality management system has now been applied in Nhon Trach Plant in Vietnam, Shanghai Plant and Shantou Plant in China as an approach to quality improvement.

*ISO9001 is an international standard for quality management systems established by the International Organization for Standardization in 1987.

| Registered company | PLUS Corporation Furniture Companyn |

|---|---|

| Date of first registration | February 23, 1998 |

| Registration number | NQA-0081A |

| Scope of registration | Products Planning, Design/Development, Manufacture, Supply and Maintenance of Service Parts for Office Furniture, Commercial Facility Furniture and Home Use Furniture; Wholesale, Retail of Room Equipment; Design/Development and Construction Control of Interior Decoration |

| Registration examining authority | Nippon Kaiji Kentei Quality Assurance Ltd. |

Information on Product Safety and Quality Issues

In the event of a serious accident caused by our product or service, we promptly report the incident to the relevant authorities under the legal obligation. Depending on the severity of the damage and the frequency of the occurrence, we directly disclose the information to customers through newspapers and our official website. We also gather information from our customers, providing any necessary information to our customers.

Quality Control at Maebashi Plant

Maebashi Plant, a production base of furniture products, is a part of PLUS LAND industrial complex. With the site area of about 460,000 sqm, the complex is located in the Kanzawa area of Maebashi City, a region blessed with nature such as Mt. Akagi, one of the best 100 Mountains in Japan, and the Kanzawa River. The plant produces steel desks, along with chairs, partitions, storage units, conference desks and a variety of other office furniture.

Throughout the years in operation, Maebashi Plant has accumulated experience and knowledge on cost reduction, making efforts such as standardization of parts without compromising quality. We also constantly work to increase the level of technical skill of our employees. As part of this initiative, we award Master status to employees who gets technical qualification set by the national or regional government. We strive to improve quality and technical performance every day. The other example is an introduction of BIMA complex machine for twin wooden top boards, which enhance our customization capacity.

Quality Control at Vietnam Plant

PLUS Vietnam Industrial Co., Ltd (Dong Nai Province, Vietnam) is our main manufacturing hub for stationery products. When established in 1995, the factory started out as a stapler manufacturing plant, consisting of only 25 employees. 20 years later, approximately 2,400 employees work to deliver 4,000 SKUs of PLUS stationery out into the world. P.V.I. is also playing a key role in the PLUS global sales strategies as a distribution hub.

The quality culture has taken root in P.V.I., with high skills and quality awareness of each employee. Every employee, regardless of their job title, shares their ideas, and the work manual is revised when necessary. As a result, we have successfully passed factory inspections in accordance with international standards.

We have shown great results in our accumulation of technology and experience, by automating production processes that previously could only be done manually, as well as enhancing productivity through improvement activities, and effecting improvements in quality and production safety.

The Quality Control Department at our Bien Hoa Plant is engaged in quality improvement and defective prevention including receiving inspection for incoming parts and final inspection before shipment.

PLUS Vietnam Industrial Co., Ltd. (P.V.I) orchestrates the automation department and automation upgrade team and has created 428 machines to automate the production of our tape and file products, driven by the motto “Free minded, Inventive and Positive approach”.

Since November 2015, the automated and semi-automated machinery designed and created by P.V.I is labeled with a “Made in P.V.I.” sticker.

Single work cell line

Automatic torque measurement device

Press fitting machine for the tape product

Continuous press fitting machine for knobs

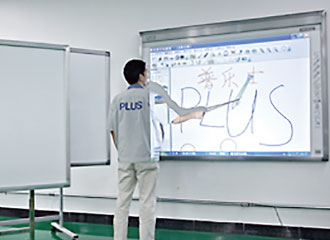

Quality Control at Shanghai and Shantou Plants

China is our second largest base for manufacturing of stationery and office products.

PLUS Stationery Shanghai Co., Ltd. (Shanghai City, China) manufactures file products, OA labels and correction tape, while SHANTOU PLUS INSTRUMENTS CO,.LTD. (Shantou City, China) manufactures products such as copy boards, whiteboards and cutting machines.

Shanghai Plant

Shantou Plant

PLUS Shanghai Plant started operation in 2005, and expanded and relocated its base in September 2012. Adding to files and OA labels, they started manufacturing correction tapes which is our main product in Asian countries, aiming to increase sales in China.

With a plan for full automatization of the production lines in the near future, the plant continues to improve its product quality as well as productivity.

Flat file production line

Label production line

Drawings and statement of inspection standards displayed during inspection before shipping

Our Shantou Plant was established in 2000. Originally producing copy boards and the peripheral devices, it began manufacturing whiteboard in 2012, and paper trimer and laser pointer in 2014. With these unique and sophisticated products, it aims to introduce new meeting styles by building sales networks in China with its local partner distributors.

Both our Shanghai Plant and our Shantou plant obtained ISO9001 certification. Employees are trained to improve product quality. Each employee is encouraged to work on how to maintain quality and doing better each day.

Logistics quality management

PLUS Logistics Corporation, a logistic subsidiary of PLUS, is a front-line and customer-facing logistic partner that aims to provide high quality services under the motto “No.1 reputation.” The business has built an optimized logistic system that harnesses interior and furniture construction capabilities unmatched by other logistic companies.

Procurement Policy and Guideline

Based on our philosophy “Unique Value-Higher Satisfaction” and quality standard, we implement procurement standards throughout PLUS Group in corporation with our business partners based on fair agreements.

PLUS Group Procurement Policy and Guideline

- 1. Compliance with and implementation of fair trade practices and corporate ethics

We conduct impartial and fair trades according to international regulations, laws of each country we operate in, and corporate ethics. - 2. Respect for human rights, adequate working conditions and health and safety

We respect human rights of all people involved in our business activities, and provide adequate working conditions that ensure health and safety. - 3. Improvement of quality and safety

We work on quality improvement according to PLUS Group Quality Policy to assure our customers that our products and services are safe and reliable. - 4. Environmental conservation

We strive to protect and improve the earth’s environment and build a sustainable society according to PLUS Group Environmental Policy. - 5. Complete Information Management

We strictly control all confidential and personal information involved in our procurement trading in an appropriate way. - 6. Contribution to society

We engage in social contribution activities as a member of local society.